Summary:

1. Look at the design requirements1) The drawings should be complete and detailed, and the way of expression should be ...

1. Look at the design requirements

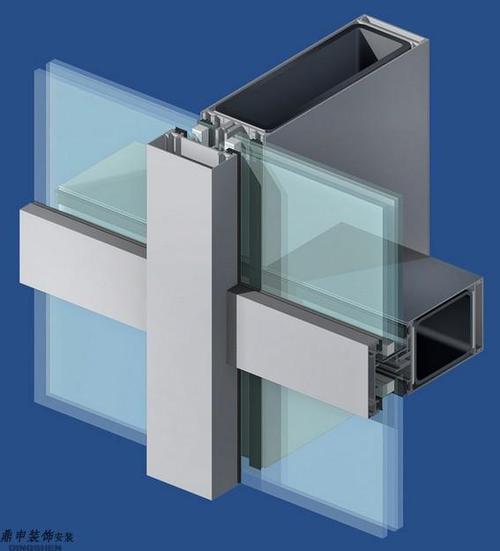

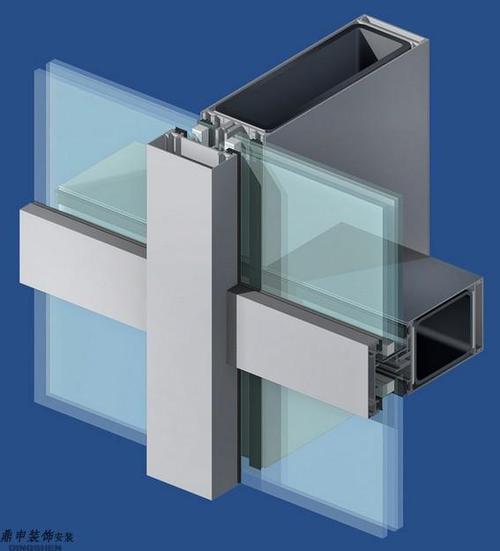

1) The drawings should be complete and detailed, and the way of expression should be standardized. Construction drawing descriptions and construction requirements, node diagrams, calculation of embedded anchor nodes, calculation of stress and deformation of

curtain wall keel frame under vertical load and horizontal load, lightning protection, fire prevention, and drainage measures must be complete.

2) The design of the curtain wall should take measures to prevent rainwater leakage. The cross-sectional form of the glass curtain wall column and beam should be designed according to the principle of equal pressure. The leakage hole should be set at the location that is prone to leakage, and it is easy to cause condensation. The condensed water discharge pipe should be set up at the water part, and the water drain hole should be drilled in strict accordance with the specified requirements when the component is made. The sealing material of the opening part should be made of neoprene or silicone rubber.

3) Insulating gaskets (generally 1mm thick) or other anti-corrosion measures should be installed at the contact between different metal materials of the glass curtain wall. The size of the insulating sheet should not be less than the contact area to ensure that the aluminum alloy column is in direct contact with the different steel connectors. Flexible gaskets should be provided at the contact with the beam.

2. Selection of materials.

1) Curtain wall profiles should meet the high-precision requirements specified in the current national standard "Aluminum Alloy Building Profiles" GB/T5237, and the thickness of the anodic oxide film should not be less than "General Specification for Aluminum and Aluminum Alloy Anodized Anodized Films" The index of AA15 level specified in GB8013 is: the wall thickness of the structural member profile is not less than 3mm. The minimum average film thickness is 15 дm, and the minimum local film thickness is 12 дm. The surface color of the anodized aluminum alloy profile is basically uniform, and no defects such as corrosion spots, welding injuries, black spots, and oxide film shedding are allowed.

2) Safety glass should be adopted for frame-supported glass curtain wall. The point-supported glass curtain wall supported by glass ribs shall be adopted for the glass ribs of tempered protruding layer glass. Safety glass should be used in public places where there is a high flow of people, young people or children's activities, and parts that are prone to impact during use.

3) The structural adhesive must have good tensile strength, peel strength, tear strength and elastic modulus, and it also plays a role in shock absorption. Structural silicone sealant and weather-resistant silicone sealant must be provided by the material supplier with the product quality warranty period quality certificate and the compatibility and adhesion test report of the structural silicone sealant with the contact material, and the same should be noted Whether the quality of the structural glue of the batch is stable, structural silicone glue beyond the expiration date shall not be used, weatherproof glue and structural glue shall not be substituted for each other, especially structural glue shall not be used as weatherproof glue. When designing and selecting, you should ask the manufacturer for the displacement bearing capacity data and quality assurance certificate of its structural adhesive. Imported silicone structural sealant should have a commodity inspection report. In order to ensure the quality of the curtain wall project, the same brand of silicone structural sealant and weather-resistant adhesive should be selected for the same curtain wall project, which not only has better compatibility, but also facilitates the identification of responsibilities in the event of project quality problems.Hidden frame and semi-hidden frame glass curtain wall, glass and aluminum profile must be bonded with neutral silicone structural sealant; when full glass curtain wall and point supporting curtain wall are coated with coated glass, acid silicone structural sealant should not be used. Because all materials containing metal elements will react with the acidic silicone structural sealant and cause adhesion failure; when using non-coated glass, the acidic silicone structural sealant can be used. Hidden frame, semi-hidden frame and point-supported glass curtain wall used for secondary sealing of insulating glass must use silicone structural sealant. The polysulfide sealant used in the secondary sealing of ordinary insulating glass has poor UV resistance and is not compatible with silicone structural sealant, so it is not allowed to be used for insulating glass in curtain walls. For full glass curtain walls that use glue joints to transmit force, the glue joints must be made of silicone structural sealant.

4) The rubber sealing strip should adopt EPDM, chloroprene rubber or silicone rubber, which meets the requirements of HG/T3099 and GB/T5574.

5) The hardware should meet the design requirements, and stainless steel materials that are easy to rust should not be used. The stainless steel should be shielded during electric welding to prevent electric welding sparks from splashing on the stainless steel and causing rust.

6) Use materials with fireproof grade of A or B1 in strict accordance with the requirements of the specification. When the fireproof grade of the material is not clear, samples should be taken for testing.